Have you ever tried hiding the remote controller of the air conditioner simply to get rid of the extensive current bill? If so, inverter type air conditioners are just the thing for you!

This particular strategy of energy saving is suggested in a popular TV advertisement, nowadays. As it suggests, with this inverter type air conditioners energy saving up to 60% can be expected. Therefore, it is worth to have a look, how this new phase of technology accounts for the energy efficiency and the performance of the air conditioners.

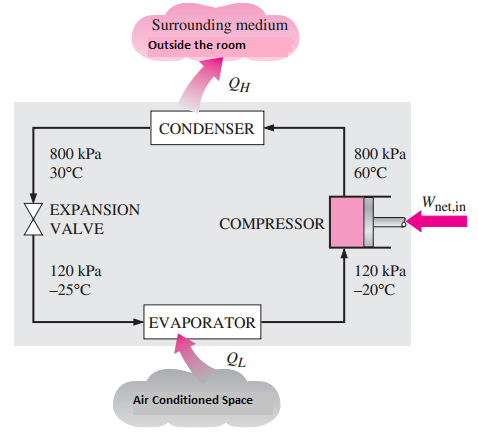

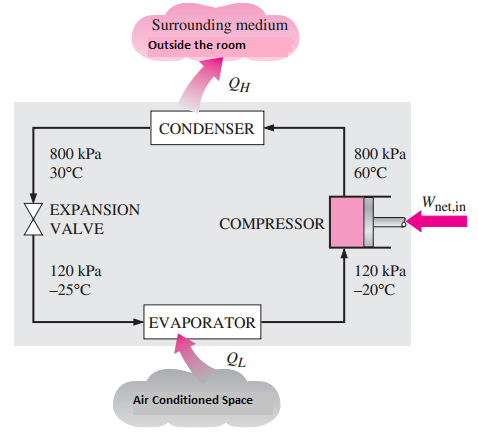

The basic operation of the air conditioners is to extract the heat energy from a compartment area and release it to the outer environment.Therefore, when maintaining the air conditioned space, at a lower temperature, air conditioner has to extract heat energy from a lower temperature medium, and release it to a higher temperature medium. From the second law of thermodynamics (Clausius statement), for this to happen, there should be some external work done somewhere in the cycle. The work needed for this thermodynamic cycle is done by the compressor of the air conditioner.

|

| Operation principle schematic |

|

| Thermodynamic cycle in Air conditioners |

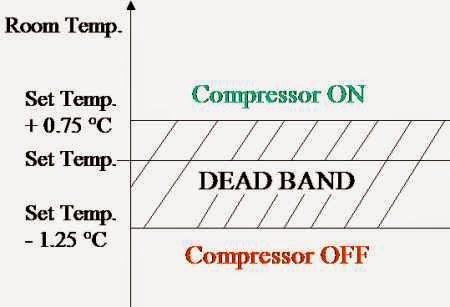

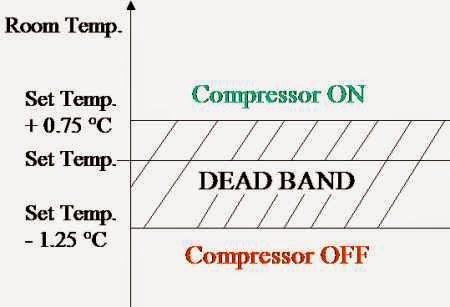

The point of the cycle, where air conditioning can be easily controlled, is the compressor motor. In conventional air conditioners, on off control of compressor is used to maintain the temperature of the air conditioned space around the set value. That is, if the temperature of the room is below the ‘set value-some tolerance’, compressor will completely turn off, whereas if the room temperature rises above the ‘set value + some tolerance’, compressor will completely turn on. A dead band is there to avoid rapid fluctuations of the response around the set point, which would occur otherwise.

|

| On- Off control operation |

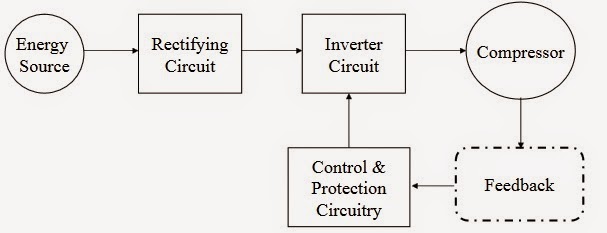

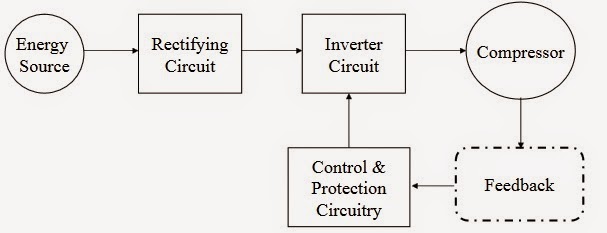

In inverter type air conditioners, in contrast, the

conventional on- off type control is replaced with a wide range of speed

control technology. That is, with this

new technology, the speed controlling of the compressor is possible rather than

just turning on and off. To control the

speed of the compressor motor (which is an induction motor), over a wide range,

a variable frequency motor drive is used.

|

| Control block diagram of the compressor |

|

| Operation block diagram of the inverter |

At stating of the air conditioner powerful cooling is required to reach the set temperature.When the set temperature is reached,only a little power is sufficient to maintain the achieved temperature when it comes to inverter type air conditioners. This is achieved by controlling the compressor speed. In contrast, with conventional air conditioners, only the on-off control of high the speed compressor is possible.That in turn results in large fluctuations of temperature.Subsequently this leads to a wasteful consumption of energy.

How much of this wasted energy you can save by replacing the old air conditioner with an inverter type one mainly depends on the factors such as, environmental conditions, thermal insulation of the compartment area, set temperature, rate of change of the room conditions, etc.

Another major plus point with inverter type air conditioners, over the conventional type is its ability to reach the set temperature smoothly and quickly. And also it is capable of maintaining the air conditioned space around the set temperature with a lower tolerance. Due to more precise temperature control, enhanced room comfort can be expected.

With the conventional type air conditioners, sharp fluctuations of voltage which would disturb the other electricity consumers and appliances could occur due to frequent on/off of the compressor. But with inverter type air conditioners, that issue is completely eliminated.

Anyway, with the added complexity due to the introduction of power electronics, production cost tends to increase proportionately. Moreover repairing and troubleshooting of this new inverter, is neither simple nor easy as it is with the conventional one.

Whether you like it or not, conventional air conditioners are now being rapidly replaced by this newly introduced member!

References:

Article By: Thisandu Kahingala

Monday, December 22, 2014

Monday, December 22, 2014

This project is to design a dynamic traffic light controller, which adopts according to real time traffic flow and then control the switching of signals according to the traffic condition. In this design, induction loops are used as vehicle detectors and the control of traffic lights is done dynamically by a fuzzy logic controller in such a way to get a smooth flow of traffic. The control signals from main controller to the controllers at each traffic light is done through wireless communication which is another significant feature in this design.

This project is to design a dynamic traffic light controller, which adopts according to real time traffic flow and then control the switching of signals according to the traffic condition. In this design, induction loops are used as vehicle detectors and the control of traffic lights is done dynamically by a fuzzy logic controller in such a way to get a smooth flow of traffic. The control signals from main controller to the controllers at each traffic light is done through wireless communication which is another significant feature in this design. Posted in: Researches and Projects

Posted in: Researches and Projects Sunday, November 30, 2014

Sunday, November 30, 2014

Crude oil reserves are rapidly diminishing. Therefore the prices of the petroleum are rising. Further the burning of petroleum oil causes deadly effects towards the environment with millions of vehicles in the world. That number is enough to have a clear image about the amount of the petroleum burnt per second in the world. These clues give us the evidence to switch our energy sources currently used in vehicles to a clean energy source.

Crude oil reserves are rapidly diminishing. Therefore the prices of the petroleum are rising. Further the burning of petroleum oil causes deadly effects towards the environment with millions of vehicles in the world. That number is enough to have a clear image about the amount of the petroleum burnt per second in the world. These clues give us the evidence to switch our energy sources currently used in vehicles to a clean energy source. Posted in: Electrical Industry

Posted in: Electrical Industry Sunday, November 09, 2014

Sunday, November 09, 2014

It is important for an Electrical Engineering undergraduate to know about power systems in theoretical as well as in a practical approach. Thus, a power system simulator is ideal to understand practically the theories learnt in class. Commercially available models though are in existent, the endeavor was taken to design and build a power system simulator, as a final year project. The simulator is a scaled down model of the actual power system prevailing in the Sri Lankan context. Though it is a scaled down model, all electrical components such as generators, relays, circuit breaker panels are all actual industry used components. As a continuing project many aspects are being developed piece by piece under the guidance of the supervisors and with financial support from the industry. This project provides the basis for the fulfillment of the aspiration by the Department of Electrical Engineering, University of Moratuwa, to give a firsthand experience for the undergraduates before they encounter industrial training.

It is important for an Electrical Engineering undergraduate to know about power systems in theoretical as well as in a practical approach. Thus, a power system simulator is ideal to understand practically the theories learnt in class. Commercially available models though are in existent, the endeavor was taken to design and build a power system simulator, as a final year project. The simulator is a scaled down model of the actual power system prevailing in the Sri Lankan context. Though it is a scaled down model, all electrical components such as generators, relays, circuit breaker panels are all actual industry used components. As a continuing project many aspects are being developed piece by piece under the guidance of the supervisors and with financial support from the industry. This project provides the basis for the fulfillment of the aspiration by the Department of Electrical Engineering, University of Moratuwa, to give a firsthand experience for the undergraduates before they encounter industrial training.

Posted in: Researches and Projects

Posted in: Researches and Projects Sunday, November 09, 2014

Sunday, November 09, 2014

The aim of the project is to develop an active suspension system for vehicles. In this project, the main objective is to suppress the vibrations caused due to the imperfections of the road surface and give a better stability to the sprung mass. In order to achieve this goal, the suspension system changes its characteristics and suppress the vibrations according to the vibration level of the road and applied disturbances.

The aim of the project is to develop an active suspension system for vehicles. In this project, the main objective is to suppress the vibrations caused due to the imperfections of the road surface and give a better stability to the sprung mass. In order to achieve this goal, the suspension system changes its characteristics and suppress the vibrations according to the vibration level of the road and applied disturbances.

Posted in: Researches and Projects

Posted in: Researches and Projects Thursday, November 06, 2014

Thursday, November 06, 2014

Though there exists an e-waste management concept in Sri Lanka, most of the people are not aware about that, as it is only limited to the Colombo city area. But as a result of technological development the usage of electrical and electronic equipment has spread all over the country. Therefore it is very much essential to implement a national level waste management program.

Though there exists an e-waste management concept in Sri Lanka, most of the people are not aware about that, as it is only limited to the Colombo city area. But as a result of technological development the usage of electrical and electronic equipment has spread all over the country. Therefore it is very much essential to implement a national level waste management program. Posted in: Sustainable Energy and Policy

Posted in: Sustainable Energy and Policy Wednesday, September 03, 2014

Wednesday, September 03, 2014

Posted in: Utility and Social

Posted in: Utility and Social